Product

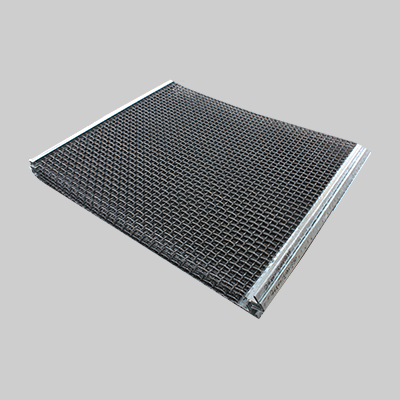

Vibrating Screen Parts

We can supply a comprehensive range of spare parts for screening plant. We stock Camber Bars, Cloth Clamp Plates, Cross Members and Mainframes, Screen Shafts, Feed and Discharge Trays, Labyrinths, Distance Rings, Bearing Housings, Specialist Bolts etc.

Types of Screening Equipment

Incline Screens

No matter where you want to place them in your circuit, it's true that incline screens are typically the best bet. This is because they harness the power of gravity to reduce power consumption. As a result, the incline configuration has better capacity abilities when operating at similar speeds versus horizontal screens. Inclined screen machines can vibrate in linear or elliptical patterns, or in a circular motion. The latter tends to be preferred in continuous feed setups that screen large material.

Horizontal Screens

If you're limited at your quarry or mine site by vertical clearance challenges that prevent the screen incline from being constructed at the proper angle—often about 20 degrees on the top deck—you will have to choose a horizontal screen. Horizontal screens are also commonly used in portable plants, or if you're feeding from a dredge in water-intensive operations. Horizontal screens will typically vibrate with either linear motion or an elliptical motion. Both movement patterns are effective, but the linear—or straight-line—motion produces high G-forces to help dislodge material and propel it across the screen.